Silverinstruments

SILVER AUTOMATION INSTRUMENTS https://www.silverinstruments.com industrial process instrumentations solve varies demanding in Agricultural Irrigation, Industrial Water & Wastewater, Factory Process Control, Oil & Gas, Electric Power Generation.etc

How Do Flow Meters Work

Flow meters are devices that are wont to live the flow of a particular liquid or gas. They'll live these substances in terms of the volumetrical flow or the mass flow rate. The volumetrical flow is mostly given in m3/second. The mass flow is given in kg/second. Flow meters have several applications. For people, a peak flow meter will live the respiratory organ capability. This can be conjointly utilized by individuals with asthma and may be wont to verify if an respiratory disease is close at hand. Apart from that, flow meters are utilized in several industries, just like the food process trade, water management, semi conductor fabrication and lots of others. This text can provides a transient summary of however flow meters work. For more info about high viscosity flow meter, Visit our website.

Flow meters are usually classified by the principal that governs their operation or probably by their applications. As an example, mass flow meters live the flow of a medium in terms of it's mass.

However, there are forms of mass flow meters that use totally different strategies to require this activity. One example of this can be the Coriolis flow meter that uses the event to see the mass of a fluid passing through 2 moving tubes or pipes. The thought being that by understanding the modification within the characteristics of the wave patterns in the moving tubes, you'll be able to correlate the flow of the substance passing through.

Ultrasonic and Doppler shift flow meters conjointly use the changes caused to sound waves to correlate a rate of flow for the medium passing through the meter. Within the case of the inaudible flow meter, 2 transmitters of inaudible sound waves are placed at the ends of a pipe wherever the live is to require place. Every transmitter sends a pulse of sound.

The transmitters conjointly act as a receiver of the wave sent by the opposite transmitter. One pulse of sound is shipped within the direction of the flow of the liquid and therefore the alternative is sent against the flow. If numerous constants are notable concerning the metal of the pipe and therefore the liquid or gas passing through the pipe, a rate of flow may be derived from the time it takes each wave to achieve the receiver.For more info about high viscosity flow meter, Visit our website here https://www.silverinstruments.com

Doppler shift flow meters use the changes within the frequency and amplitude of a wave once it bounces off particulate in the liquid that's being measured to see the flow.

A a lot of ancient kind of flow meter is that the variable space flow meter that uses a float during a label tube. Once a substance passes through the tube, the float is displaced by the flow. By taking the reading from the label tube a sign of the flow may be determined. this can be the principle of the height flow meter used for respiratory organ capability and bronchial asthma.

Guided Wave Radar Level Instrument

High frequency microwave pulses travels along the detecting component(steel rope or rod)and reflects when veaching the product surface.The time from emission to reception is proportional to the distance between the surface and the reference plane on the

instrument.

Features

- SDGW5X equipped with the advanced microprocessor and unique EchoDiscovery echo processing technology can be used in severe ambience.

- SDGW5X with extremely low emission power, can be mounted on various metal or nonmetal vessels, harmless towards the environment and human beings.

- There are multiple options available in choosing various process connection and detecting component, which enables SDGW5X to be applied in a broad extent of applications, such as high temperature, high pressure, medium with small dielectric constant and etc.

Ultrasonic Level Meter

HL Ultrasonic level meter for continuous non-contact level measurement in liquids and solids. It consists of probe and host, both of which are plastic leak-proof structure. The HL series can be widely applied to the metallurgical, chemical, electricity and oil industries.

Sanitary and Hygienic Electromagnetic Flow meter

Magnetic Flow meter sensor is widely used to measure different kind conductive liquids. SHD-SE13 series Magmeter sensor is a sanitary type flow measuring device.It can measure tap water, tomato paste, liquid egg, molasses, juice, vinegar and so on which are widely used in food-processing, beer and pharmaceutical industries.

Sanitary Hygienic Turbine Flow meter

Turbine flow meters are well-suited for applications on clean, low to moderate viscosity liquids flow measurements.

SLW-Tri Series Hygienic Turbine Flow meters provide a durable and cost efficient ways to measure the liquid fluids in excellent precise and stable repeatability. This sanitary TUF is designed for the dairy, beverage, food processing and pharmaceutical industries. Such as for clean water, milk, palm oil, edible oil, vegetable oil, fish oil flow measurement and so on. The design of this type flowmeter is also suitable for cleaning-in-place (CIP).

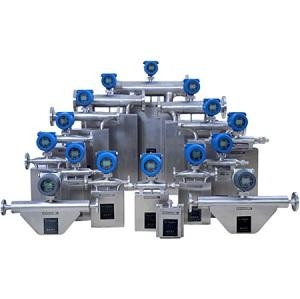

Balanced Flow Meter

Balanced Flow Meter Features

- High accuracy

Multi hole balanced flow sensor is actually a flow rectifier, can effectively eliminate swirl and distorted velocity distribution improvements, the ideal state of the flow field approximation, the conventional measure for level 0.5, high accuracy measurement for level 0.2.

- High turn down ratio

Multi hole balanced flow sensor is a with multi holes, select the appropriate equivalent diameter ratio, favor the lower limit of the flow also give consideration to the upper limit flow ,making the conventional measure flow turndown ratio of 10:1, if appropriate parameter selection, turndown ratio can be raised to 20: 1 ~ 30:1

- Low requirement for straight pipe

Balanced flow sensor can adjust the flow stable and pressure recovery 2 times faster than conventional orifice throttling device, greatly reducing the requirement for straight pipe. Lower straight pipe section can be as small in most cases 0.5D ~ 2D, a balanced flow meter can save a lot of straight pipe sections, in particular pipe with expensive special materials.

- Low Pressure loss

Balanced flow meter multi hole symmetrical design reduces the formation of vortices and turbulence of friction, reducing the kinetic energy loss. In the same working condition without reducing the differential pressure, balance flow meter can reduce 1/2~1/3 permanent pressure loss comparing with the conventional throttle device to reduce the cost.

- Good repeatability and long-term stability

Balanced flow sensor of SILVER AUTOMATION INSTRUMENTS is with stable flow to improved repeatability up 0.1%.

Balanced flow meter multiple circulation holes dispersed by force, no acute wear, its β value of long-term unchanged to maintain stability, the whole instrument with no moving parts , extend the service life of 5 to 10 times faster than conventional throttling device .

- Not easy to block by dirty

Porous symmetrical balanced design reduces the formation of vortex turbulent shear force fit , thereby greatly reducing the formation of dead zone residence , dirty media to ensure a plurality of holes pass , reducing the chance of fluid holes are blocked .

- Wide application range

Working temperature and pressure of balanced flow sensor is decided by pipe and flange material, it can reach to 800 ℃, 42MPa or higher temperature, pressure medium. Suitable for cryogenic fluid LNG liquid air , liquid ammonia , liquid oxygen, liquid fluoride , liquefied ethylene, liquid hydrogen , chlorine , etc., can effectively prevent vaporization , measuring good effect.